It me for sure.

It me for sure.

Nice! That’s not bad at all. Any trouble with print consistency or maintenance?

Nice. Larger bed size definitely fits my needs better.

Yes, this definitely should be a part of the energy mix, we are about to experience an energy crisis in the US due to bad changes in policy. We need to deploy wind at all scales.

Their prototype unit is 400 watts, based on their deck their target is residential use.

While “a lot” would fit in a the footprint of a large turbine, 42,500 would not, which is how many would be needed to be equivalent to the large turbines the article is talking about, and I’d bet that many Harmony Turbines would cost more as well.

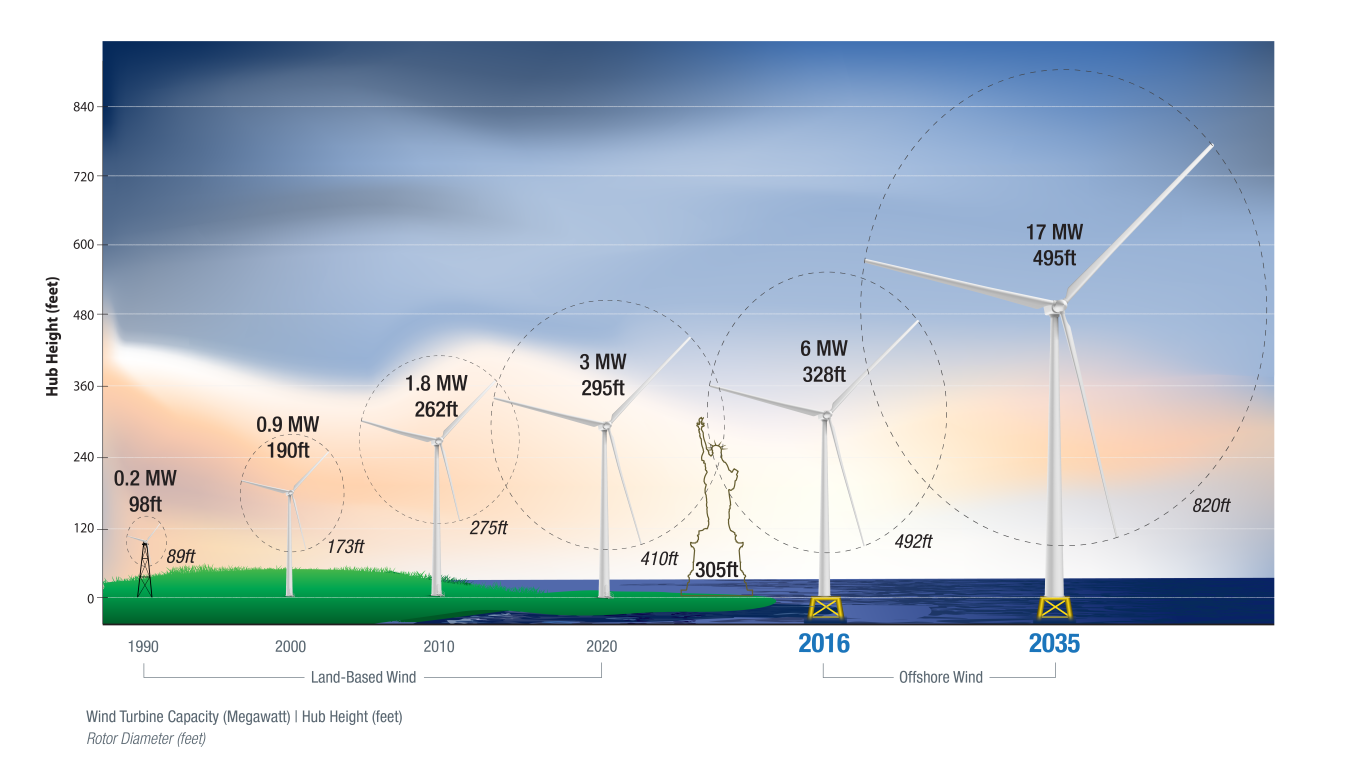

Scale efficiency for grid scale wind projects is the bottom line, and bot accessing steadier and stronger high altitude winds with taller turbines and using larger diameter blades gain efficiency beyond what any fleet of smaller turbines can match.

Not to say that larger scale vertical axis turbines are completely out of the picture, but they suffer from irregular bearing loading which wears out the drive train much faster among other issues. As of now large scale horizontal axis bladed turbines are far ahead in term of both cost and space efficiency. It would take something very groundbreaking to change that.

No need to die on this hill, it’s just different technologies for different applications, there is a place for both.

Open secret of the surgery business is that the CRNAs (specialty anesthesia nurses) do all the actual anesthesia work, the Anesthesiologist’s job is really to pick the anesthetic based on patient history and bloodwork, do the calculations for dosing based on body weight, and attend for interventions if something goes wrong. The Nurse he put in charge when he left was almost certainly already doing all the work anyway and he was just twiddling his thumbs with a hard on in the corner.

Check out this DOE page for more info on turbine scale: https://www.energy.gov/eere/articles/wind-turbines-bigger-better

To not dismiss your perspective out of hand, in order to use smaller vertical-type mills and still tap higher altitude winds on masts would require support structures that can keep many more turbines aloft to supply the same electricity, and the electrical infrastructure to merge all the turbine electrical output and balance the loads to give a stable denoised power output to the grid.

The result is a much lower weight to power density in the smaller turbines, meaning much more expensive structural supports, and much more expensive power routing and station infrastructure. This makes such projects non-viable as they wouldnt be able to charge enough for the electricity to pay off the infrastructure over the lifetime of the turbines.

Smaller turbines like the one you posted DO have a great place in the power mix, for example for potential installation at the top of skyscrapers where the support infrastructure is already paid for by other uses (though the loads have to be accommodated by the building design, which still adds cost), or in low-altitude areas where steady winds exist and there is specific moderate electrical demand, such as in valley ports on islands or more remote coastal towns. In those cases larger mills would overproduce electricity demand, so smaller turbines at lower altitude are a good fit.

The forces on a blade of this size are truly staggering, when you think about how long a lever they are attached to only one side, its clear that the issue is not only strength at the seam of a proposed joint but also the impact any additional weight will have on the junction of the blade with the rotor. They are pushing the limits of what high pressure molded composites can handle at these scales, but still some companies have developed multi-piece turbine blades.

Generally the biggest downsides to multi-component blade technologies are that they cost substantially more, and they have lower operating lifespan, a bad double whammy for the profitability of a windmill.

Basically the cargo plain developers are banking on the cost per flight of each turbine blade being less than the cost of building, installing, maintaining, and replacing multi-part blades over the lifetime of the windmill, and as of now this economics pencils out. Who knows though, tech changes fast, what I wonder is whether portable blade foundries might not be possible to build the blades on-site for large windmill projects.

If you want to get into the nitty gritty I found this presentation very helpful: https://windmillstech.com/wind-turbine-design/

Doesn’t tap the higher altitude stronger winds.

Check out reAM250 powder bed fusion 3d printer

Looks like a step towards true industrial metal printing.

“Open source hardware is hardware whose design is made publicly available so that anyone can study, modify, distribute, make, and sell the design or hardware based on that design. The hardware’s source, the design from which it is made, is available in the preferred format for making modifications to it.” - https://oshwa.org/resources/open-source-hardware-definition/

Well, there are ways to jailbreak kindles and use third party software like this: https://github.com/koreader/koreader/wiki/Installation-on-Kindle-devices

So I make a pile of sticks, that pile of sticks is open source? No.

You are confusing using open source tools with being an open source project. Using open source tools is great as a user, but it does not make what you do with them open source, whether it makes the activity legal or not. Publishing the design of the tool to be replicable by others is what made that tool open source in the first place for you to use.

It is the difference between “I built this house out of bricks woth my open-source backhoe” and “I built this house out of bricks this way, and here is how you can do it the same way”. Neither one is illegal, but one is an open source project and the other is just permissible under the law.

Public Domain =/= Open Source either.

Thanks for sharing your experience. I do hesitate on projects like this for this rreason, it’s always the small stuff that seems to get in the way of a streamlined experience. That said, I feel like building one rather than buying off the shelf would give me a lot more know-how about how to troubleshoot and maintain the system I am using, plus I prefer to support Open Source initiatives when I can over walled gardens.

You know, as an aside, this kind of part kitting is one of those things that I think LLMs might actually make a meaningful change in very shortly. No one wants to individually order all the parts on a BOM right now because it is a bunch of labor, but do it once with an activity log of your purchasing behavior and the sites/vendors used and there is no reason it cant be fully automated and shareable as simply as the BOM itself. Add in a function to check pricing and inventory against other related vendors and it could get quite good.

How can hardware be open without build documentation? Unlike software which is infinitely replicable and open unless obfuscate, hardware is private by default as the method of construction is effectively the “source code” and can not generally be derived without direct access to the hardware in question and disassembly. Dissassembly without reassembly instructions can only derive vocational information, and reverse engineering is required to translate that to assembly instructions which themselves are likely to differ from the prior engineer’s method.

Hardware is only open source if its assembly documentation is made openly available.

“Open source hardware is hardware whose design is made publicly available.” is the first sentence of the link you provided. Viable Hardware Design includes assembly, because as any hardware engineers will tell you a schematic is only valuable if it has been proven possible. Schematics themselves are documentation, design of hardware is documenting hardware otherwise you are crafting not designing.

End rant, lol.

Excellent!

Nice! Great list, do you run any of them?

As a side note, check out the app Mihon if you like to read comics, the seas are open for sailing if you’re that sort, or its just a great reader. Works great on Boox.

Critical for grid scale storage.