A criminal could buy an Ender3 or other extremely ubiquitous, non-internet-connected printer. Maybe used, in cash, on various marketplaces.

Filament can be bought in cash as well from a bunch of retailers and the leftover stock (evidence) easily disposed by dumping or burning/melting after the “suspect objects” are created.

Furthermore, nozzles are like $1 apiece in some cases. Printbed replacements or sheets of glass (also often used as printbed surfaces) are like $20 and can be changed often and easily. Changing these two components completely invalidates the “match” of the toolmarks.

This type of forensics is only practical if the target suspect is dumb enough to use the same settings for everything, never change a nozzle or bed, keep all his empty filament spools and receipts, pay for everything with credit cards in his name, and have a bunch of cloud-saved bambu-sliced files called “super illegal weaponry.gcode” associated with his printer.

Just more scientifically unsound forensic “evidence” for prosecutors to bamboozle juries with.

This will definitely also be one of those “only works to convict” forms of evidence like fingerprints, where the presence of a non-match will be played off as inconclusive, but a “match” will be treated as 100% definitive.

I’ll take “Sandpaper” for $200, Alex.

But… you’d need to do several test prints with the suspects 3D printer to get a matching profile right? It doesn’t seem practical but indeed every 3D printer has it’s own fingerprint.

It’s not any less practical than, for example, test firing a gun to match the rifling on its bullets to bullets found at a crime scene.

You’d also have to use the same slicer settings, similar room conditions, make sure that you have the same filament roll (assuming it’s an FDM printer), make sure that nothing hardware wise was tweaked (eg. fixing belt tension), make sure nothing software wise was tweaked (it’s nuts how much difference temp can make), make sure nothing firmware wise was tweaked, and the nozzle cant have had too many prints between the suspicious one and now (or like half of a glow in the dark or carbon fiber filled print).

Edit: and same print orientation, just turning the part direction in the slicer causes different artifacts, in extreme cases I’ve seen a part facing one way fail, but a quarter turn right or left prints flawlessly.

It’s also nuts how much difference eccentric nuts can make.

Both the ones for adjustment, and the operator.

Also the ones who think this is something with even tiny chance of being viable in court anytime soon or will persist as an effective crimebuster for any notable amount of time if they do.

The above comments have already covered many possible variations complicating things, due to the settings and positions of how the machine was used to 3d print something. The article claims 3d printing tech has nozzles that have unique signatures. They would (or at least should) need to make sure it is actually unique by cross checking with other nozzles too. Lots of them really, just to make sure.

That might require finding multiple nozzles made in the same batch as the murder weapon, preferably unused, so they could attempt to recreate the crime version, to rule it out. It might be a nozzle manufacturer causing these imperfections where each batch of 10,000 nozzles is made in an extrusion plant or injection mold or done like solder ball grid array or pipefitters and play-doh (i honestly have no idea how they are made lol) and it turns out every nozzle in the first row has the same ‘fingerprint’ that warps the same way with use.

As technology progresses, parts should (but these days, idk) be made with more durable materials, with greater precision, capable of smaller scales or higher complexity and these unique signatures disappear for any easily detectable method. That’s just the nozzles. In theory, that can apply to many if not all the parts.

I mean, Fabs for CPU are currently producing chips at what, 3 nanometers now? I just learned about electron-beam lithography too. The 3d printed smoking gun fingerprinting will be an anacronism before it’s a specialization, in my opinion.

Just a note on how nozzles are made, they are machined brass usually. They can wear pretty significantly over their lifespan too, especially if you run harsh materials (glow in the dark is harsh enough that a brass nozzle might not last a single print).

There are hardened steel nozzles, but even those are a wear item, they just wear slowly. As I said somewhere else, it’s like trying to chase down a ransom note by analyzing the shape of the lead of a pencil that may have been used to write it. Just using it changes the properties.

Is this how ghost gun printing is working? One person with a machine making and selling oodles?

If you’ve printed your own it seems like this would have limited applications, because you’ve either destroyed or lost it, or it’s still in your possession.

key excerpt:

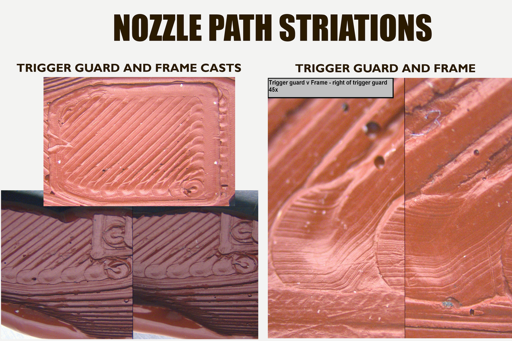

Most 3D printers work by heating up a filament—often, but not always, plastic—and extruding it through a metal nozzle. The nozzle puts down hundreds, or even thousands, of layers of the heated plastic to form a solid object. Each individual level of the print is called the print line. “So on the firearm, I’m seeing from the trigger guard—maybe print line 200—and the top of the magazine well—print line 400—the marks are staying consistent,” Garrison said.

It was an exciting discovery but it also wouldn’t be admissible as evidence in a criminal trial. Despite the promise that we may one day be able to match a printer to the object that made it, Garrison stressed that the work was in its very early days and that it would take years, perhaps even a decade, of science to work out the truth of toolmarks and 3D printers.

unless its unrelated to the nozzle it’ll be easily circumvent by replacing said nozzles.

Yeah I can’t fuckin print consistent prints on purpose, good fuckin luck doing some kind of forensic analysis about it.

Yeah, this is absurd. Also if someone makes a “ghost gun” they can easily destroy the printer before using that thing.

If someone makes a 3d-printed ghost gun, they can destroy the gun beyond any chance at recognition by tossing it into a fire.

yes and no. I think the idea here long term is similar to the printer dots on normal printers. where they track/record those from factory to the point of sale. if the nozzles leave identifying marks (something I’d totally believe) then even destroying said printer might not help you if you used a credit card to purchase it.

Unless there is something inserted into the gcode, nozzles are a wear item. You would not be able to put a consistently identifiable mark on the nozzle

I can change what an individual print line looks like to the naked eye just by something as simple as tweaking temperature or print speed. Good luck getting anything remotely consistent intentionally by clever nozzle machining.

Also, nozzles are dead simple to make, it’s literally just a large drill bit (1.75mm diameter or so) with a smaller (.05mm to 1mm) drill poking the last bit through. Tip is slightly flattened off and away it goes.

Also, as someone else said, nozzles are a wear item, it’s like trying to track a car down by the brake pads, or a pencil down by the shape of the lead at the tip, using it changes the characteristics of it.

Each individual level of the print is called the print line

It’s called a layer.

“So on the firearm, I’m seeing from the trigger guard—maybe print line 200—and the top of the magazine well—print line 400—the marks are staying consistent,” Garrison said.

…I don’t even understand what that’s supposed to mean? “The marks are staying consistent”? What marks? Consistent with what?

Even if they were able to match a print to a nozzle (which they won’t be because it’s a wear item that’s constantly changing), nozzles are cheap and replaced often. You replace them in 2 minutes.

However, none of this will stop DAs from trying to use this shit as evidence, just like all the other junk science they pay people to lie about.

Also worth pointing out:

There are other issues too. All of Law and Blair’s tests were done with one kind of 3D printer—a Prusa MK4S. There’s hundreds of different devices on the market that all behave differently. Law also pointed out that brass nozzles warp over time themselves and may produce different results after hundreds of prints and that different nozzles made from different materials may work very differently. Law would also want an examiner rate study—a formal scientific inquiry into false positives and examiner bias.