3D printer toolheads often have large blower fans with big fan ducts ending in small holes and I wonder how necessary that is.

These large part cooling setups are most of the size of the toolhead and significantly reduce print area. Blower fans also do not produce much pressure so those fan ducts greatly reduce their effectiveness.

Does it make sense to, instead of using a blower fan, use a small compressor like for an aquarium and have the airflow delivered Bowden style to a small nozzle? The airflow would be substantially higher than from a fan. Noise isn’t really an issue for a tiny compressor.

Has anyone tried this? I might eventually but don’t have the time to set it up now.

Nice, that is indeed what I meant. Recently I’ve designed a new toolhead for a 3D printer but have just used blower fans and fan ducts like any other toolhead but while designing I wondered if more weight/volume could be removed without losing functionality.

That there is precedence makes me want to design another version of the toolhead.

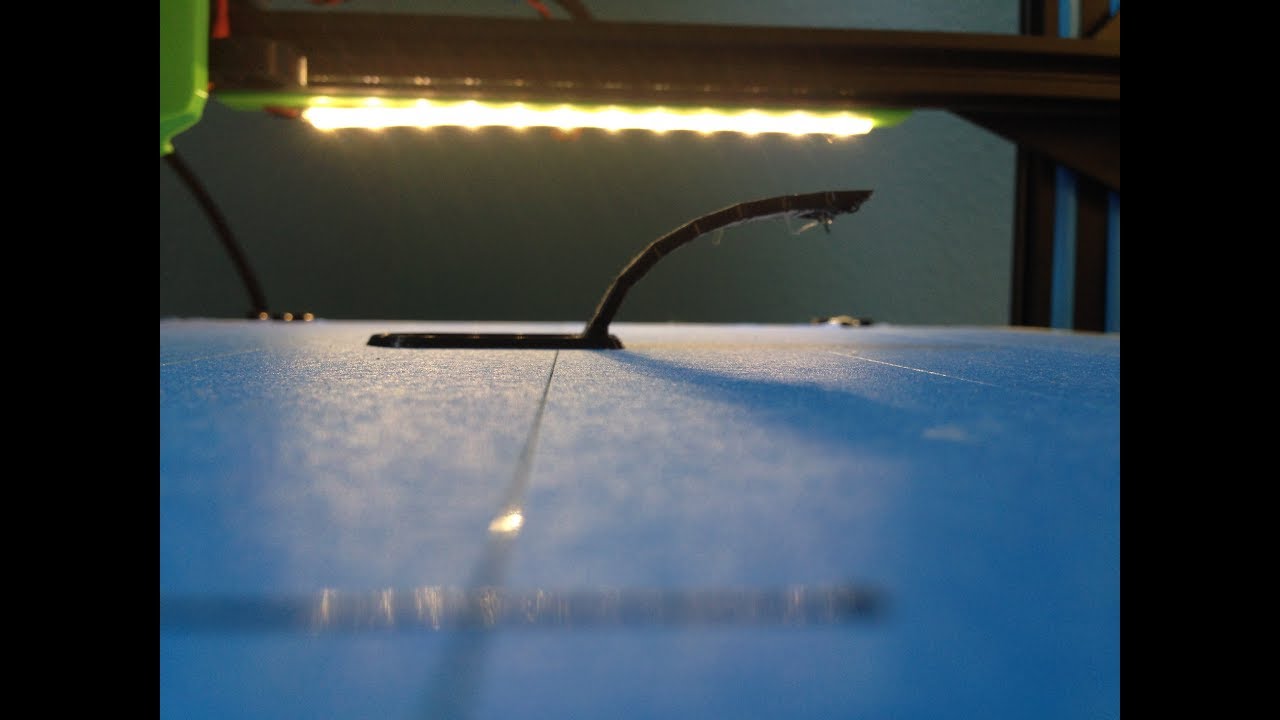

That’s definitely more how like laser cutters and cnc mills do it right? Although maybe that’s more for removing debris than cooling. Seems like a good idea, unless it’s too much pressure and starts deflecting the plastic while it’s still molten.

deflecting the plastic while it’s still molten

That was my first thought

Indeed I’d have to play with the distance between the printed plastic and the nozzle as well as air pressure, otherwise it’s a silly string machine. But that seems to be the easy part.

You will find this on many high end ultra fast printers. The compressor makes a lot more noise than a fan.

The Prusa MK3S+ duct is probably the best blower fan design for part cooling. The duct only barely enters the path of the exit from the blower unless the print head is on a flat surface that causes back pressure at the exit. Only then does the air get redirected through the duct in a useful way to get better coverage behind the nozzle.

I took this design and made it snap fit over the end of a blower instead of mounting it to the extruder print head. So I got to know it well.

If you know about the Reynolds number and how length and surface texture impact flow, almost all ducts and fans used in hobby printers are indeed garbage.

Water cooling is so cheap now, we should probably be using it for the extruder. I think the issue with small compressors is duty cycle. Like the ones for refrigerators is super quite but they have a low duty cycle time.

Cooling duct are used to precisely cool down plastic right after it was lay down without cooling down build plate (to avoid warping issue), this enable you to print bigger overhang without the need of support which end up in greater details.

Unless you have knowledge to create CFD trace, I would avoid it, they were/are tons of poor designs like ring duct which are very ineffective/unprecise. You don’t need really high pressure but blower fan are better than radial fan for almost all designs is why you see them the most (they are also more than pressure which are to take into account but don’t recall).

As of reducing print bed, it doesn’t, But if you wish to full the plate with parts and use the “print one object at a time” setting, it will reduce the number of object you can put on a plate, otherwise it will knock down parts.

As an exemple, my first printer which was the OG ender 3 with petsfang duct get better overhangs than my bambulab A1 with stock duct.

Well. I didn’t mean if part cooling was even necessary at all. Of course it is when printing anything with overhangs. I wanted to replace blower fans with a small compressor on the side of the 3D printer.